|

Enovation Controls operates today as a stand-alone subsidiary of Helios Technologies. With an internationally diverse team of over 300 employees, we serve customers around the world with global sales, manufacturing and application engineering operations. We partner directly with OEMs and support a worldwide network of authorized distributors and system integrators.

Our tradition of innovation was founded on the pioneering spirit of Frank W. “Pat” Murphy and his search for simple, reliable engine protection. In 1939, he transformed the world of engine instrumentation with the release of his innovative Safety Switch and the forming of FW Murphy Manufacturing. In 2009, FW Murphy merged with EControls, forming Enovation Controls which operated four business units: Power Controls, Vehicle Technologies, Natural Gas Production Controls, and Fuel Systems. The Murphy brand along with the Power Controls and Vehicle Technologies business units were acquired by Sun Hydraulics in 2016 and today serve diverse applications across many markets.

The rich history of rugged and reliable Murphy products has propelled Enovation Controls to become the well-respected and trusted partner to major engine and equipment manufacturers around the world. Simply put, our brand has become synonymous with innovation by providing cutting-edge, market-leading solutions demanded by today’s technology driven customers. |

|

| DISPLAYS |

|

|

POWERVIEW® EDGE-TO-EDGE DISPLAYS

The PowerView family of edge-to-edge displays bring the latest in technology and design to any application without compromising on usability or protection. Designed for use with or without gloves, in bright sunlight or harsh weather, the glass-front PowerView family of edge-to-edge displays have a display for any size application.

- POWERVIEW® 1200

- POWERVIEW® 1100

- POWERVIEW® 700

- POWERVIEW® 500

|

|

POWERVIEW® TACTILE-BUTTON DISPLAYS

The PowerView family of tactile-button displays give operators comfortable controls designed for use without or without gloves. PowerView displays are built strong with robust protection against harsh environments and best-in-class screens for unstrained viewability in bright sunlight. Bring user-friendly control to your application, with PowerView tactile-button displays.

- POWERVIEW® 780B

- POWERVIEW® 780

- POWERVIEW® 485

- POWERVIEW® 450

- POWERVIEW® 350

- POWERVIEW® 380

- POWERVIEW® 101

- POWERVIEW® 25

|

|

POWERVISION CONFIGURATION STUDIO®

PowerVision Configuration Studio® software allows developers to customize multiple aspects of a PowerView display®.

The developer suite offers programmers varying levels of control – from base-level display options to in-depth custom programming with C/C++ syntax scripting capabilities. PowerVision Configuration Studio provides several protocols for machine integration and more than 100 commonly used J1939 and NMEA messages and diagnostic functions. PowerVision Configuration Studio is licensed and available on SPARK Software Manager.

Graphic toolsets for the design and scaling of text, gauge and bar-graph data

Multi-layered screens for customized backgrounds, instruments, graphics and surrounds; day/night modes; warning, diagnostic and button-push ‘pop-ups’; video images

State-machines with graphical building of state-machine models

Data simulation for off-line viewing of configurations

Adaptable configurations for multiple display sizes |

|

OPENVIEWTM EDGE-TO-EDGE DISPLAYS

The OpenView family of edge-to-edge displays begins the next generation of superior displays engineered by Enovation Controls. Designed specifically on an open platform, the OpenView family of displays allows developers to design User Experiences and Application Logic with their preferred toolset, such as Crank Storyboard, Qt, or HTML5. Building on the rugged legacy of the PowerView displays, the new OpenView displays expand the possibilities for any application.

- OPENVIEWTM S70

- OPENVIEWTM S50

|

|

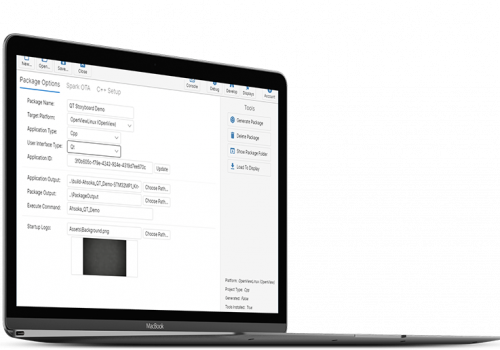

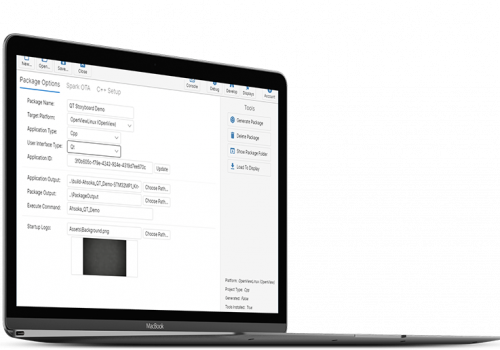

OPENPVTM SOFTWARE PLATFORM

OpenPVTM Software Platform is a sophisticated set of tools that allows developers to design the user experience of an OpenViewTM display with 3rd party development tools like Qt, Crank Storyboard, and HTML5.

The developer toolkit offers programmers:

- Project Configuration (Dev Langage, UI, etc

- Hardware Selection (For Device Specific Capabilities)

- Package Generation (Generate PVX1 Files for distribution)

- Device Communication (Load To Target)

- OTA Integration (When using Spark)

- RPC Based API’s (Using Proto – TCP/IP)

- Startup and Install Management (“No Reboot” installs)

- BSP Firmware Flashing Support (DFU Firmware Flash)

|

|

| CONTROLLERS |

|

From plug-and-play to fully configurable control, our Murphy PowerCore® Controller lineup is flexible for a wide range of engines and applications. Looking for auto start or manual start? Various throttling options? Mechanical or electronic engine control? Our rugged IP67 rated controllers and panels are all Tier 4 Final and Stage V ready and up to the task.

- POWERCORE® MPC‑20

- POWERCORE® MPC‑10

- POWERCORE® TEC-10

- EMC-6 & EMC-6L

- CASCADE

- KEYSTART

- EMC SERIES

|

|

| PANELS |

|

From plug-and-play to fully configurable control, our rugged Panel Systems are flexible for a wide range of engines and applications. Looking for auto start or manual start? Various throttling options? Mechanical or electronic engine control? Our rugged IP67 rated panels are final Tier4/Stage IV ready and are up to the task.

- READY TO RUN PANELS

- ML2000 PANELS

- ML1000-4X PANELS

- MLC485 PANELS

- MLC380 PANELS

- MGC100 PANELS

- MURPHYLINK® (ML25-ML150)

- MARINE ENGINE PANELS

- WHB SERIES

|

|

| CAN I/O MODULES |

|

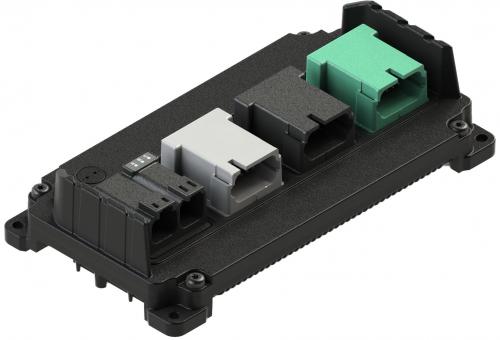

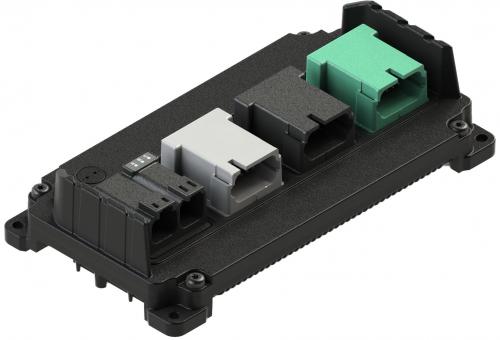

Take your integration to the next level with superior control, enhanced diagnostics and increased efficiency. Our rugged power distribution, CAN I/O and fan control modules are designed to complete any system for total equipment control.

- IX3212 INTELLIGENT XPANSION™ PDM

- POWERCORE® CXM-110

- XM500

- CANDRIVE™

- MECAN™

- FUELCAN™

- SENDERCAN®

- ZERO OFF

- MURPHY INDUSTRIAL HARNESSES

|

|

| HYDRAULIC CONTROLS |

|

We offer easy-to-apply, environmentally ruggedized electronic controllers. Our controllers have the capability to be user adjustable locally or pre-programmed to suit virtually any application requiring an electro-hydraulic solution, and are universally compatible with all major hydraulic OEM proportional products.

- UCONTROL™ MACHINE CONTROLLERS

- MVP-C SERIES

- DRC SERIES

- HGC-2 SERIES

|

|

| PROCESS MONITORING INSTRUMENTS |

|

Murphy offers hundreds of products that monitor and control pumps, generators, and more. Our control systems for industrial operations monitor pressure, temperature, liquid level, overspeed, time and vibration. We cover it all, from simple start/stop operation to sophisticated automation systems incorporating microcontrollers and remote communications.We provide cost-effective, perfectly suited products for our customers, and have been doing it for over 70 years.

- GAUGES

- LEVEL DEVICES

- SENSORS

- ELECTRO / MECHANICAL CONTROLLERS

- BATTERY CHARGERS

- SWITCHES & ANNUNCIATORS

- VALVES

|

|

LM500 / LM500-TF

The LM500 maintains oil level on any size engine.

As crankcase oil level drops, the LM500 float also drops and opens the Thumb-Valve™. This allows oil to flow from the supply tank through the LM500 and into the crankcase. When proper level is achieved in the crankcase, the LM500 float rises causing the Thumb-Valve to close off further oil flow. If the clean oil supply is depleted and oil level continues to fall, the low-level switch will operate an alarm or equipment shutdown. |

|

SENTINEL 300P SERIES

Murphy Sentinel 300P series battery chargers provide automatic, fast and accurate charging of standby batteries.

Sentinel advanced chargers ensure optimal battery power, lifetime and reliability in demanding applications such as power generators, fire-pumps, and critical engine-driven equipment. Switch mode power technology gives a low-ripple DC charge output, plus wide AC supply voltage tolerance, in a compact, light and power-efficient package. Unlike some generic chargers, Sentinel’s multistage DC output is optimized for your battery type and application – Lead Acid or NiCd; sealed or vented cells; ‘wet’, AGM or Gel electrolyte; lead antimony or calcium plates, cell temperature – all critical factors for maintaining battery health, preventing under/over charge and ensuring peak performance. |